Aquastore® glass-fused-to-steel tanks are the premium liquid storage technology. With over 100,000 structures installed in over 70 countries around the world, Aquastore tanks are proven to last longer and have greater lifetime value than any other storage application available. Aquastore tanks require the lowest maintenance and never need to be recoated or repainted during their entire lifecycle.

- NEVER needs re-painting or re-coating

- Longer tank life

- Low routine maintenance

- 100% holiday-free steel sheets

- Manufactured in ISO 9001:2008 factory

- Conforms to wide range of standards including AWWA D103, AISC, FM codes and NFPA Standard 22

- Lowest life cycle cost of any tank type

Aquastore® tanks are erected from the top down using a specialized jacking system. This building method is quick, efficient and it also allows the tanks to be expanded vertically in the future.

About Aquastore Glass-Fused to Steel

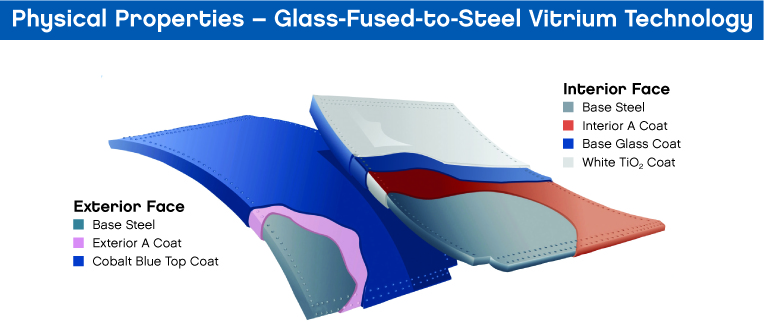

Aquastore tanks feature Vitrium™ glass-fused-to-steel technology. Vitrium is a proprietary TiO2 glassing process applied in a 3-coat, 1-fire procedure to create a chemical bond and an inert barrier for both the interior and exterior tank surfaces. Vitrium glass-fused-to-steel offers the best performance of any tank coating with a bond that is significantly better than the industry’s best epoxy formula.

Glass Frit

Glass frit is specially formulated to produce the distinctive cobalt blue Aquastore glass coating.

Edgecoat II

Aquastore tanks now feature Edgecoat™ II technology – the ONLY process in the world that provides optimum glass encapsulation on all (4) sides of sheet edges.

Edgecoat II sheets are mechanically rounded to specific radii that provides maximum glass adhesion to steel. The combination delivers the maximum corrosion resistance of Vitrium glass coating with the greatest protection on every sheet.

- Highest quality finish

- Glass is applied on all (4) sides of the sheet offering the greatest protection

- No sharp edges on tank sheets, eliminating safety hazards

- Edges are engineered to ensure optimum radii for each individual gauge of steel providing the maximum and consistent glass edge

- 5 mils of glass encapsulation on every sheet edge

Photos

TecStore™ tanks are modular factory-coated epoxy steel tanks for liquid storage. Designed and manufactured to stringent requirements, TecStore tanks employ identical structural steel, engineering designs and hardware used in Aquastore tanks to offer the same reliable storage for all the same markets.

TecStore tanks offer experienced, fast and economical construction with a proven track record of storage success in situations where Aquastore glass-fused-to-steel tanks may not be needed. With over 250,000 epoxy coated tanks in 125 countries performing in thousands of applications, no other epoxy coated tank can match TecStore’s design, manufacturing and construction.

Kuo-Lon™ is the powder epoxy system used on all TecStore tanks. The Kuo-Lon coating process is done by applying thermosetting epoxy powder to steel sheets under tight manufacturing processes and numerous process controls to provide exceptions physical properties.

- Factory process controls eliminate many common contamination issues

- No coating delamination

- No deterioration due to UV exposure

- Consistent coating thickness from sheet to sheet

- High interior and exterior corrosion resistance

- 100% holiday-free sheets

- AWWA D103, NSF 61, FDA and AISC approvlas

Bolted stainless steel TecStore™ tanks are also available. These tanks are intended for use in industrial and commercial liquid storage applications and are available in a wide range of capacities and sizes.

Photos

Technical Material Links

MASSI supplies and installs CST Covers clear span aluminum geodesic domes for use on Aquastore® and TecStore® tanks. Installation is provided for both ground or elevated tanks, other types of new or existing tanks, as well as concrete and earthen reservoirs. Applications include: potable water, water treatment plants, fire suppression water, wastewater treatment, landfill leachate, process water, industrial/petrochemical, frac flowback and production brine, anaerobic digestion.

Clear span aluminum geodesic domes are self-supporting, lightweight, and strong. Built to industry design standards they can withstand high snow loads, wind loads, extreme temperatures, and attached equipment loads. The domes can be supplied with manways, walkways, dormers, skylights, vents, equipment access hatches, pipe sleeves, nozzles, and insulation. They can be anodized or coated to meet architectural considerations.

Photos